Pharmaceutical Reactor (CE approved)

Basic Info

Model No.: MC-5-U

Product Description

Model NO.: MC-5-U Material: Stainless Steel Structure: Multiple Parallel Agitator Model: Ribbon Agitator Heating: Outside (Inside) Coil Heating Automatic Grade: Automatic Trademark: Mingchen Origin: China Type: Reaction Kettle Capacity: >1000L Pressure: Positive Tower Reactor Type: Plate Tower Reactor Heat Transfer Structure: Jacketed Condition: New Specification: CE 2014 New Arrival, Chemical Mixing Tank,Fermenter/ Pharmaceutical Reactor (CE approved)

Specification :

Chemical mixing tank is a container with an agitator for mixing, dispersing and reaction of different materials in chemical production. It is widely used in chemical, food, pharmaceuticals, resin, coating, paint, printing ink industry. It can be either dished end type or flat lid type, with level gauges, temperature detectors and display device. Usually, it has manhole, sight glass, feeding inlet, discharging outlet and spare openings. For different production process and reaction materials, we will have different designs and configurations, mainly displayed on its shape, overall size, sanitary requirement, seal effect, with condenser, heat exchanger, pressure sensor, temperature sensor and load cell. Various agitators and discharging modes for option.

Details:

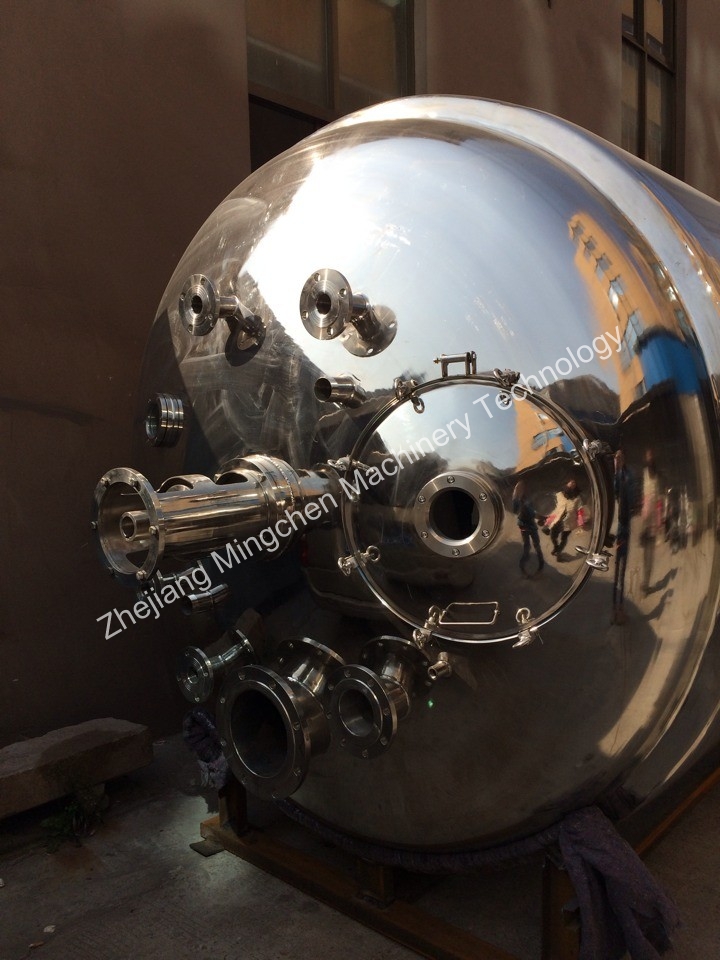

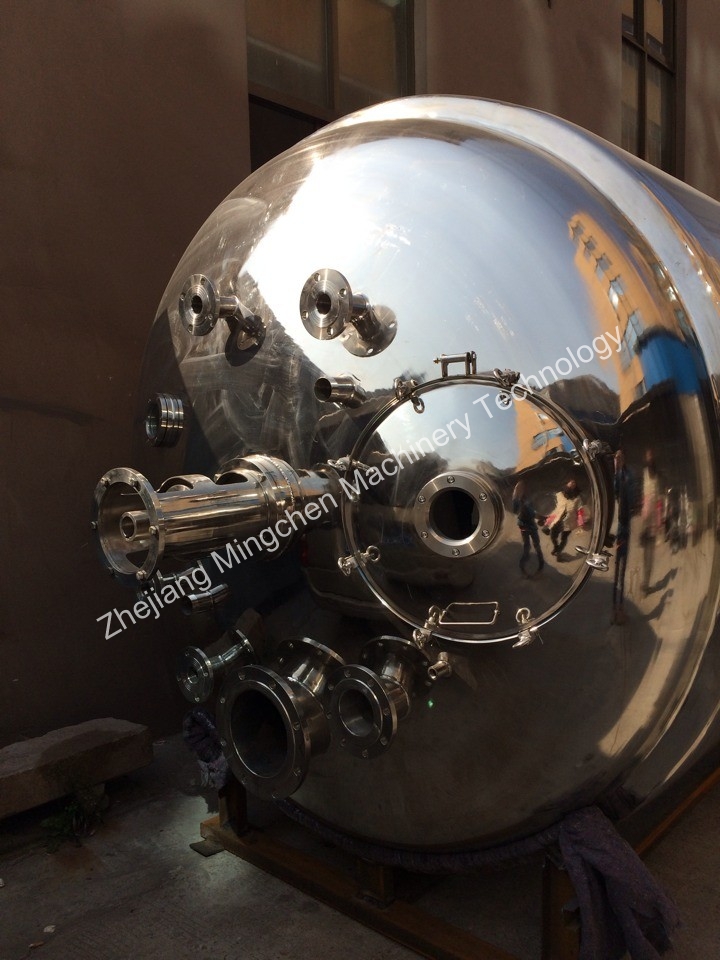

1. Usually it has jacket or coiler pipe for cooling/heating 2. The wetted part material can be enamel, C.S., S.S or non-metal material 3. Surface treatment: acid-dipping, polishing, corrosion resistant coating 4. With lifting lugs or supporting legs 5. Custom-made design is available

Characteristics: 1. It is available online CIP cleaning ( only suitable for enclosed structure) 2. Designed in accordance with sanitary requirements, so the structural design is very user-friendly, easy to operate, healthy to store. 3. The inner surface is mirror-polished (roughness Ra≤0.4µm); the welding of all kinds of nozzles, endoscopic, manholes and the pot adopt stretch flanging process arc transition, easy to clean with no dead ends, ensure the reliability and stability in the production process.

Contact us if you need more details on Mixing Tank. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Pharmaceutical Reactor、Liquid Mixing Tank. If these products fail to match your need, please contact us and we would like to provide relevant information.

Specification :

Chemical mixing tank is a container with an agitator for mixing, dispersing and reaction of different materials in chemical production. It is widely used in chemical, food, pharmaceuticals, resin, coating, paint, printing ink industry. It can be either dished end type or flat lid type, with level gauges, temperature detectors and display device. Usually, it has manhole, sight glass, feeding inlet, discharging outlet and spare openings. For different production process and reaction materials, we will have different designs and configurations, mainly displayed on its shape, overall size, sanitary requirement, seal effect, with condenser, heat exchanger, pressure sensor, temperature sensor and load cell. Various agitators and discharging modes for option.

Details:

1. Usually it has jacket or coiler pipe for cooling/heating 2. The wetted part material can be enamel, C.S., S.S or non-metal material 3. Surface treatment: acid-dipping, polishing, corrosion resistant coating 4. With lifting lugs or supporting legs 5. Custom-made design is available

Characteristics: 1. It is available online CIP cleaning ( only suitable for enclosed structure) 2. Designed in accordance with sanitary requirements, so the structural design is very user-friendly, easy to operate, healthy to store. 3. The inner surface is mirror-polished (roughness Ra≤0.4µm); the welding of all kinds of nozzles, endoscopic, manholes and the pot adopt stretch flanging process arc transition, easy to clean with no dead ends, ensure the reliability and stability in the production process.

| Capacity | Working Pressure(Mpa) | Working Temp. ( ºC) | Mixing speed (R/M) | H (mm) | H1 (mm) | D (mm) | D1 (mm) | h ( mm) |

| 100 | 0.25 | 100 | 0 - 720 | 1750 | 450 | Φ750 | Φ550 | 300 |

| 200 | 0.25 | 100 | 0 - 720 | 1950 | 600 | Φ850 | Φ650 | 300 |

| 600 | 0.25 | 100 | 0 - 720 | 2500 | 1000 | Φ1100 | Φ900 | 350 |

| 1000 | 0.25 | 100 | 0 - 720 | 2850 | 1200 | Φ1300 | Φ1100 | 350 |

| 2000 | 0.25 | 100 | 0 - 720 | 3350 | 1500 | Φ1500 | Φ1300 | 350 |

| 3000 | 0.25 | 100 | 0 - 720 | 3700 | 1700 | Φ1700 | Φ1500 | 350 |

| 5000 | 0.25 | 100 | 0 - 720 | 4250 | 2000 | Φ2000 | Φ1800 | 400 |

| 10000 | 0.25 | 100 | 0 - 720 | 5000 | 2500 | Φ2500 | Φ2300 | 400 |

Contact us if you need more details on Mixing Tank. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Pharmaceutical Reactor、Liquid Mixing Tank. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Mixing Tanks

Premium Related Products

Other Products

Hot Products

Stainless Steel Pharmaceutical BottleGood Quliaty Sanitary Centrifugal PumpBrite Beer Tank for MicrobreweryVodka Distilling Boiler for Salesanitary stainless steel sight glassConstant Pressure Modulating Valve (Cpm Valve)sanitary rotary spray cleaning ballStainless steel sanitary filter housingStainless steel sanitary manhole coversanitary stainless steel high shear emulsifying tank

Quality Assuredtilting food cooking kettlesanitary liquid powder mixersanitary mixing tank with agitator/ food mixing tankstainless steel food colloid millstainless steel homogenizer pump with CE approvedHigh shear mixer