EPS sandwich roofing sheet production line

Basic Info

Model No.: Customizing

Product Description

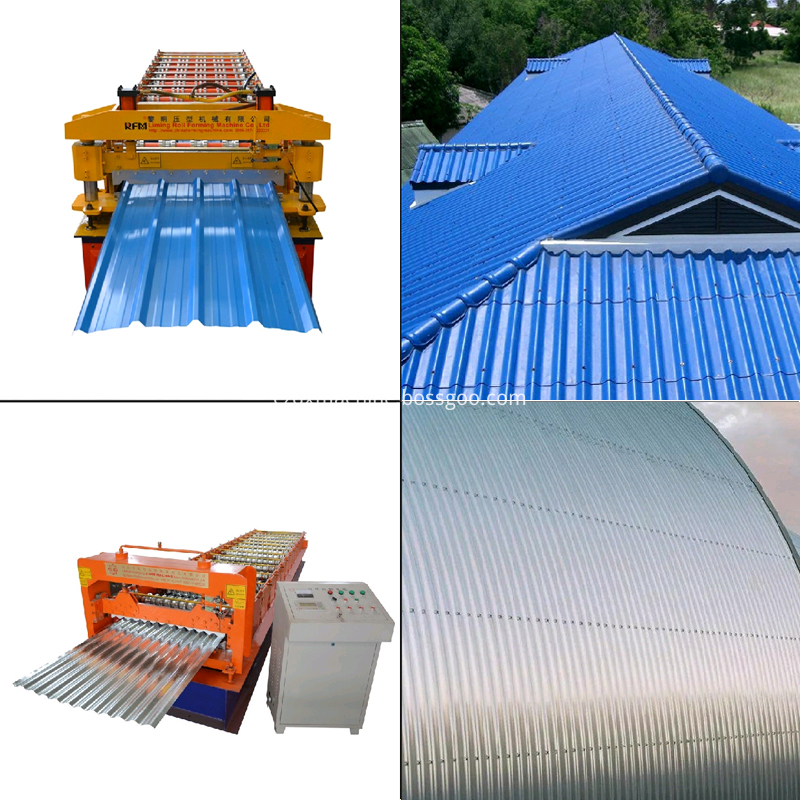

EPS sandwich roofing sheet Production line

The fully automatic sandwich panel roll forming machine is the best machine which can produce the color steel and EPS or rock wool composite board, which is also named sandwich panel machine. It is special machinery equipment using the pneumatic, electric and mechanical as a whole to produce the color steel heat preservation, sandwich panel.

The working speed uses the frequency conversion stepless speed regulation, and can composite the corrugated sandwich panel one-time.

The fully automatic sandwich panel roll forming machine use the full automatic control system with high integrated network, to achieve production information management, so as to make the automation system more advantageous, with the operation, maintenance, maintenance and mechanical debugging, mold replacement easily and so on.

1 Main moter power: 32KW

2 out line dimension of machine: 33m*2.5m*2.5m

3 Total weight: 10T

4 Processing speed: 0-5m/min

5 the thickness of upper steell plate: 0.3-0.8mm

6 the feeding width of upper steel plate: 1000/1200/1250mm

7 the thickness of lower steel plate: 0.3-0.8mm

8 the feeding width of lower steel plate: 1000/1200/1250mm

9 sandwich material: EPS/rock wool/PU/glass wool/foam

10 the thickness: 38-298mm

11 the width of stocket board: 950/1150mm

12 the width of H board: 1000/1200mm

13 the whole sandwich panel lien includes load car, up roll forming machine, down roll forming machine,roof corrugated roll forming imachine, roller unit,heat unit, glue nunit,double belt machine, saw belt cutter unit and production table

14. Material of main equipment:

(1)Roll material:high grade NO.45 forged steel,plate hard chrome on the surface of roller with thickness 0.05mm.

(2)Active shaft material:high grade No.45 carbon wrought steel at diameter 75mm

(3)Cutter blade:Cr12 mould steel with quenched treatment

(4)Producing flow:

Decoiling the sheet-sheet guiding-roll forming-measure length-cutting the panel-panels to the supporter

NOTE: we are capable of designing machine as your drawing and all the plate types can be changed according to your need.

Applications:

It use for industrial workshop, residential house, warehouse, simple steel shed etc.

1.Our machine can use galvanized steel sheet,colored armor plate or aluminum plate as the material plate.

2.Controlling by computer,PL display, operations easy, running is steady and reliable,endurable, maintenance-free.

3.We can make and design what kinds of roll forming machine according to the request of customers.

4. After sales service:

We provide the technical support for whole life of our machines.

If you need, we could arrange our technical staff to go abroad.

OUR COMPANY

Packing and shipping

Nude,with waterproof cloth and stow-wood.Imported computer control system packed with waterproof cloth and card board.

- 2.This producing line is maintained free of charge for 18 months.When the machine is used in China,we will install and debug the machine for free;if it is used at abroad,we will send the professional technician to debug.Buyers should take all the fees for technicians travelling abroad.

- 3.All the parts in the roll forming machine is free to maintain all the life,if in 18 months our company bear the cost for exchanged the broken part like the new parts cost and express cost,if more than 18 month,we also free to maintain the broken parts but for send the new parts,the buyer need bear the express cost.

Our severs

> Warranty: 2 Years.

During the warranty period, it covers all spare parts of machines, if you find some spare parts were damaged,

those new spare parts will be supplied free by us, but normal wear and tear excepted. And the freight should be bore equally by both parties.

> We could provide technical guiding, production, installation, debugging and maintenance service to all customers. After the end of the warranty period, it`s not free.

> We will provide the technical support for the whole life of the equipment.

>TERMS:

1. Delivery: in stock

2. Package: Export Standard package for container

3. Payment: TT(30% by TT in advance, 70% by TT after you inspect the machine )

4. Validity: good for 30days

More drawing

If you have any questions for the Roofing roll forming Machine, send your Inquiry Details in the Below, Click "Send" Now!We will be 24 hours services for you .

Contact me

we warmly weclome you to visit our facory!

Product Categories : Sandwich Panel Production Line